Die-casting (knife): material and design

There are two factors that make a cardboard box reliable and strong - the first is the quality of the material chosen, and the second is the precision of the die, which we call a knife. No manufacturer wants to spend a lot of time assembling a product box due to missing fold lines or incomplete cutting.

Purpose of the blades:

Cardboard boxes must meet the following requirements:

- Ease of transportation, the possibility of placing in warehouses and pallets, the possibility of stacking

- The ability to withstand the weight of the product without the risk of deformation.

- Resistance to inevitable mechanical impact during loading, unloading and transportation.

- Easy assembly.

All these requirements are taken into account at the construction stage. After production, the boxes are delivered to the customer unassembled so that they do not take up much space. As the customer produces his product, he collects the boxes and uses them for their intended purpose.

Knives are responsible for the accuracy of folding and cutting points of the cardboard box. Knives can be roughly compared to the shapes used to cut cookies, familiar to us from childhood.

The high-quality blade cuts the cardboard with a powerful impact without bends and tears, as well as crushes the fold lines.

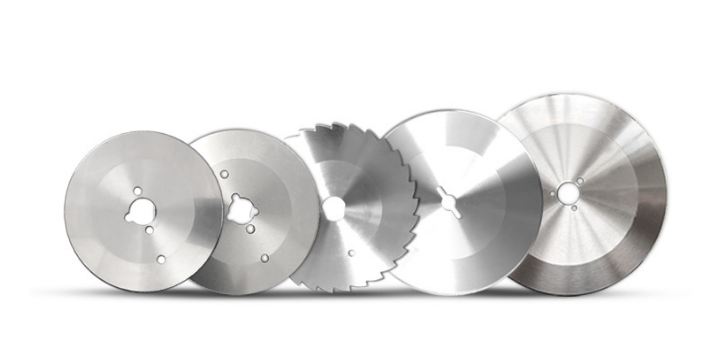

As a rule, rectangular flat knives are used in the production of small-volume (1000-5000 pieces) packaging. During mass production, rotary knives are used.

Steel bands and ejector rubbers of different heights are used depending on the thickness of the processed cardboard for long-term operation of the knives. At the same time, when it is necessary to make holes in the boxes, iron details called punches are used.

Designing knives

For the mass production of standard designs (four-valve, archival, self-assembling boxes, TV trays, etc.), packaging companies use blades of various shapes and sizes. For the production of custom-made boxes of original construction, knives are made according to those dimensions.

Making a blade is a process that requires accurate calculations and special knowledge of box design technology. Here, the main task of the designer and engineer is to ensure that all the parameters of the box to be made are included in the special program.

After the digital project is created, a mock-up of the corrugated cardboard that will be used in the box is made based on it. The test copy is tested, its compliance with the technical task is checked, it is agreed with the customer, and only then the production of the print run is started.

Materials