Why do you need microfoam cardboard?

Despite the fact that more than a hundred years have passed since the invention of corrugated board, a better material for the manufacture of boxes has not yet been found. Several variants of corrugated cardboard are used today: double, triple, five-fold and microcorrugated. Each has its own area of consumption. For example, microcorrugated cardboard is used in the production of packaging for pharmaceuticals, jewelry, perfumes and other small items that require an elegant and neat design.

About Microfiberboard

The main advantage of microcorrugated cardboard is its thinness (from 0.4 to 1.8 mm), as well as its ability to absorb shock due to its rigidity, strength, lightness and flexibility. All these qualities are manifested in small boxes. In addition, microcorrugated cardboard is characterized by a flat and smooth surface.

Structurally, this material is a three-layer corrugated board. Its main difference is in the thickness of the corrugated layer. The presence of an air gap between the flat liners provides damping properties and good thermal insulation, and the structure of the cellulose material facilitates the creation of all kinds of constructions.

The main areas of application of microcorrugated cardboard:

- Electronics, glass and porcelain products, lamps, components for office equipment, etc. small and fragile goods.

- Perfumes, creams, cosmetics, jewelry, watches, souvenirs, etc. expensive accessories

- Glasses and pencil cases.

- Mini showcases, brand promo stands, shelves and other promotional products.

- Toys, constructors, stationery.

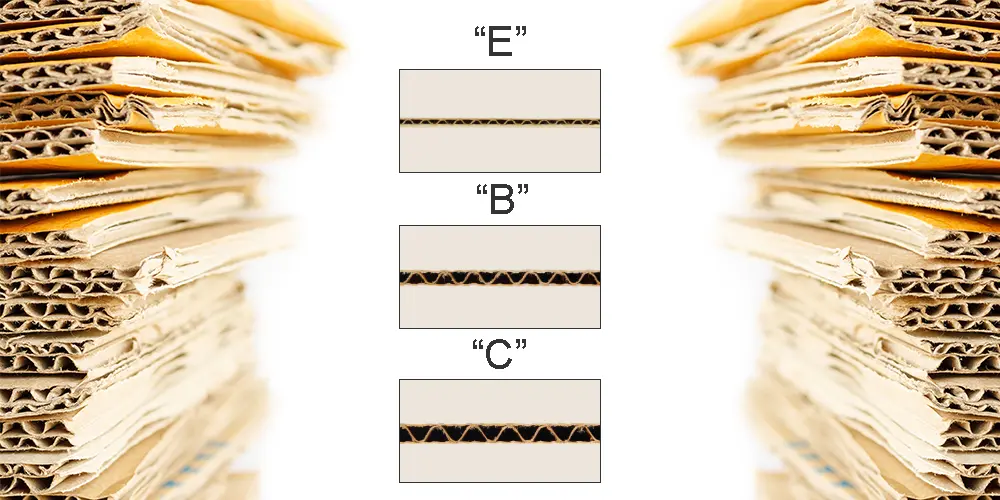

There are several types of microcorrugated cardboard, which differ according to the following parameters:

- Fluting height (in mm).

- The color and texture of the outer coating.

- The composition of the outer liner.

As a subtype of corrugated board, micro-corrugated board is denoted by the letter E of the Latin alphabet.

E-profile microcorrugated cardboard is one of the most common types of cardboard in Azerbaijan. However, this material also has its own subtypes:

- F – the wave height is between 0.8 and 1.2 mm. The material is quite flexible and is great for making small boxes..

- G – although it is quite strong and sturdy, it is thinner. Widely used for perfumes, mobile phones and other small items. The height of the corrugation is 0.6-0.8 mm.

- N – is the smallest profile with a wave height of 0.4-0.6 mm. Such cardboard is used in the production of boxes for stationery and other small products of similar size.

Depending on the color of the surface, microcorrugated cardboard is brown (for shipping boxes) or white.

The composition of the outer layer differs according to the following types of liners:

- Top liner - made entirely from primary cellulose.

- Test liner –produced from recycled material without the addition of primary cellulose.

- Kraft liner –It consists of primary and recycled cellulose in a ratio of 8 to 2.